Ba za a iya cewa zare na yau da kullun da zaren ramuka na yau da kullun ba, sai dai a ce zare na yau da kullun da reamed ramin rami, saboda zaren guda biyu iri ɗaya ne, bambancin shi ne ɓangaren sanda ba tare da zare ba.Domin bangaren zaren daya ne, karfin axial din daya ne.Akwai tazara tsakanin fili sanda wani ɓangare na talakawa angwaye da rami, da kuma transverse karfi ne kawai batu na gogayya a kan lamba surface a lokacin da angwaye da aka tightened (hakika, idan da gaske ka yi la'akari da yanke, da transverse karfi). shi ne ainihin ƙarfin juzu'i na kusoshi).Daidaitaccen kullin ramin da aka sake gyara tare da rami shine juriya, kuma ƙarfin juzu'i shine ƙarfin juzu'i na ramin da aka sake gyarawa.

Yi hankali

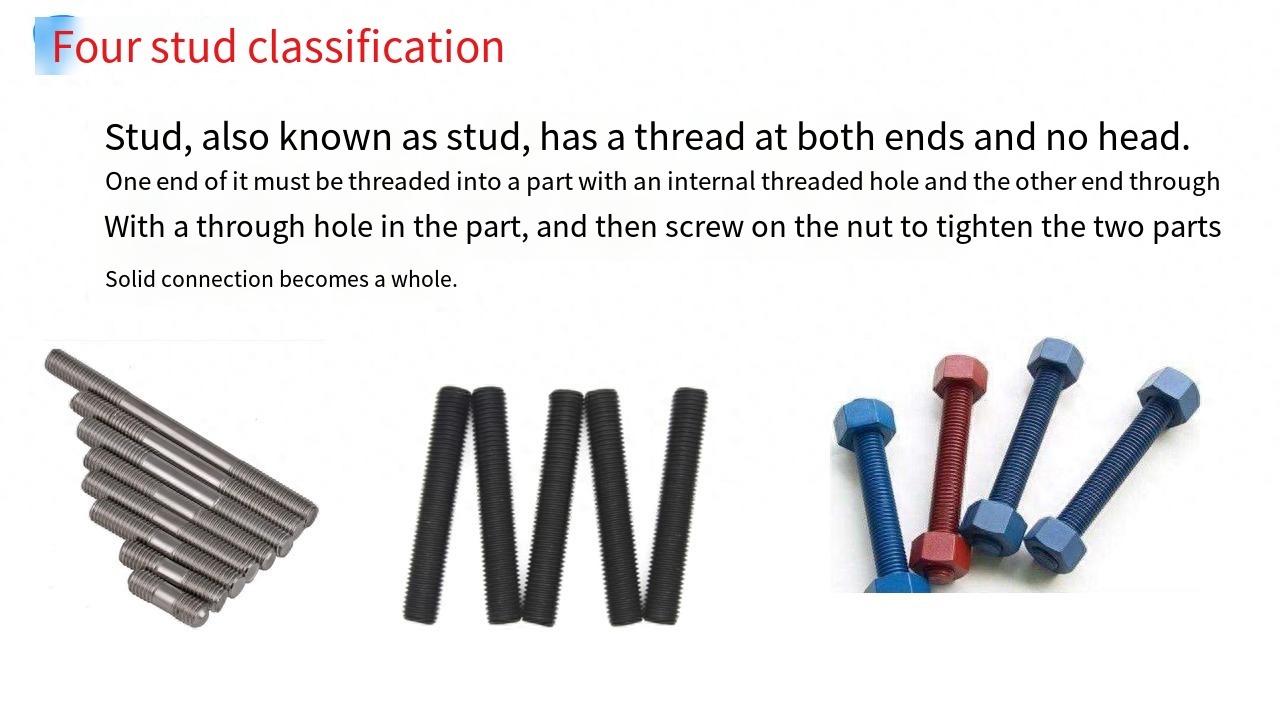

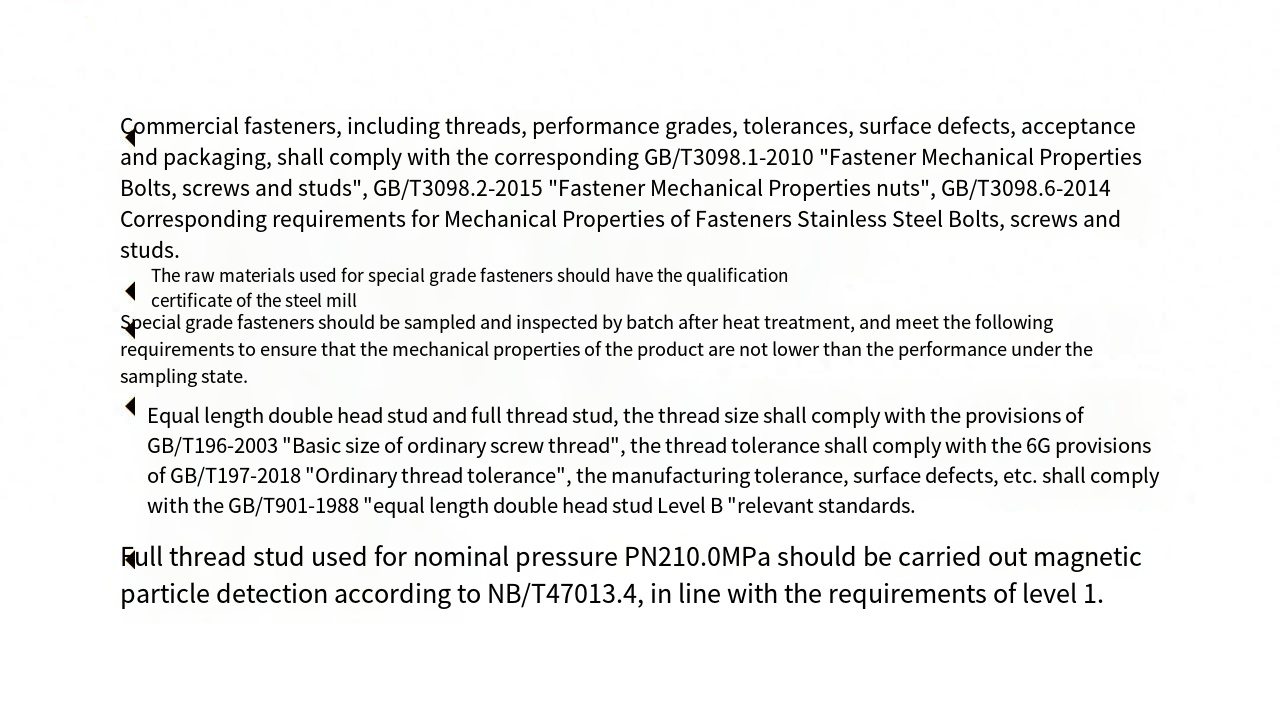

bm = 1d ninki biyu ana amfani dashi gabaɗaya don haɗin kai tsakanin sassa biyu na ƙarfe da aka haɗa;GB/T897-1988 "Bm = 1d" (bm yana nufin ƙarshen ramin ramin da ake kira screw end, tsayin bm yana da alaƙa da kayan ɓangaren da za a yi: bm = 1d don karfe). da tagulla, inda d ke nufin diamita na waje na zaren, yana nufin babban diamita.)

bm=1.25d da bm=1.5d biyu ingarma ana amfani da su gabaɗaya don haɗin haɗin simintin ƙarfe da haɗin ƙarfe;GB898-1988 "Biyu ingarma bm= 1.25d", GB899-1988 "Biyu ingarma bm=1.5d".

bm = 2d biyu ingarma ana amfani dashi gabaɗaya don haɗin haɗin haɗin gwal na aluminium da mai haɗin ƙarfe.An ba da tsohon mai haɗawa tare da rami mai zaren ciki, kuma na ƙarshe tare da rami ta hanyar rami.GB/T900-1988 "Biyu ingarma bm = 2d".

Zaren da ke gefen biyu na tsayin tsayin ingarma mai ƙare biyu dole ne a daidaita su tare da goro da wanki don sassa guda biyu da aka haɗa tare da ta ramuka.GB/T901-1988 “Equal tsayi biyu ingarma Class B”, GB/T953-1988 “Equal tsayi biyu ingarma Class C”.Ɗayan ƙarshen ingar ɗin walda ɗin yana waldawa zuwa saman ɓangaren da aka haɗa, ɗayan kuma (ƙarshen zaren) ya wuce ta ɓangaren da aka haɗa tare da rami mai wucewa, sannan a sanya mai wanki, ana murƙushe goro, don haka. cewa an haɗa sassan biyu da aka haɗa gaba ɗaya.GB/T902.1 "Welding ingarma ga manual waldi", GB/T902.2 "Welding ingarma ga baka ingarma waldi", GB/T902.3 "Welding ingarma ga makamashi ajiya waldi", GB/T902.4 "Welding ingarma ga waldi na gajeren lokaci ard ingarma”.

Hankali:

Zaren da aka yi amfani da shi akan zaren biyu (GB/T897-900) gabaɗaya zare ne na yau da kullun, kuma zaren na yau da kullun ko zaren da ya dace da canjin yanayi kuma za'a iya amfani da shi gwargwadon buƙata (bisa ga GB1167/T-1996 “Transition fit thread) ”).Daidai tsawon biyu shugaban ingarma -B sa, za a iya amfani da bisa ga need30Cr, 40Cr, 30CrMnSi, 35CrMoA40MnA ko 40B abu masana'antu, ta yi bisa ga yarjejeniya tsakanin wadata da bukatar jam'iyyun. Welding ingarma abu sinadaran abun da ke ciki, bisa ga GB / T3098 .1-2010 tanadi, amma iyakar carbon abun ciki kada ya zama mafi girma fiye da 0.20%, kuma ba za a yi da free yankan karfe.

6. Taurin: Ƙarfin abu don tsayayya da abubuwa masu wuyar gida da aka matse a cikin samansa alama ce ta aiki don auna matakin laushi da taurin kayan ƙarfe.Gwajin gwaji na nufin-taurin gwajin (Brinell, Rockwell, Vickers) Abubuwan buƙatun shirye-shiryen samfuri: Ƙarshen samfurin guda biyu daidai yake, saman yana lebur, kuma ba a yarda da mai ko oxide ba.

Gwajin yanayi 10 ~ 35°

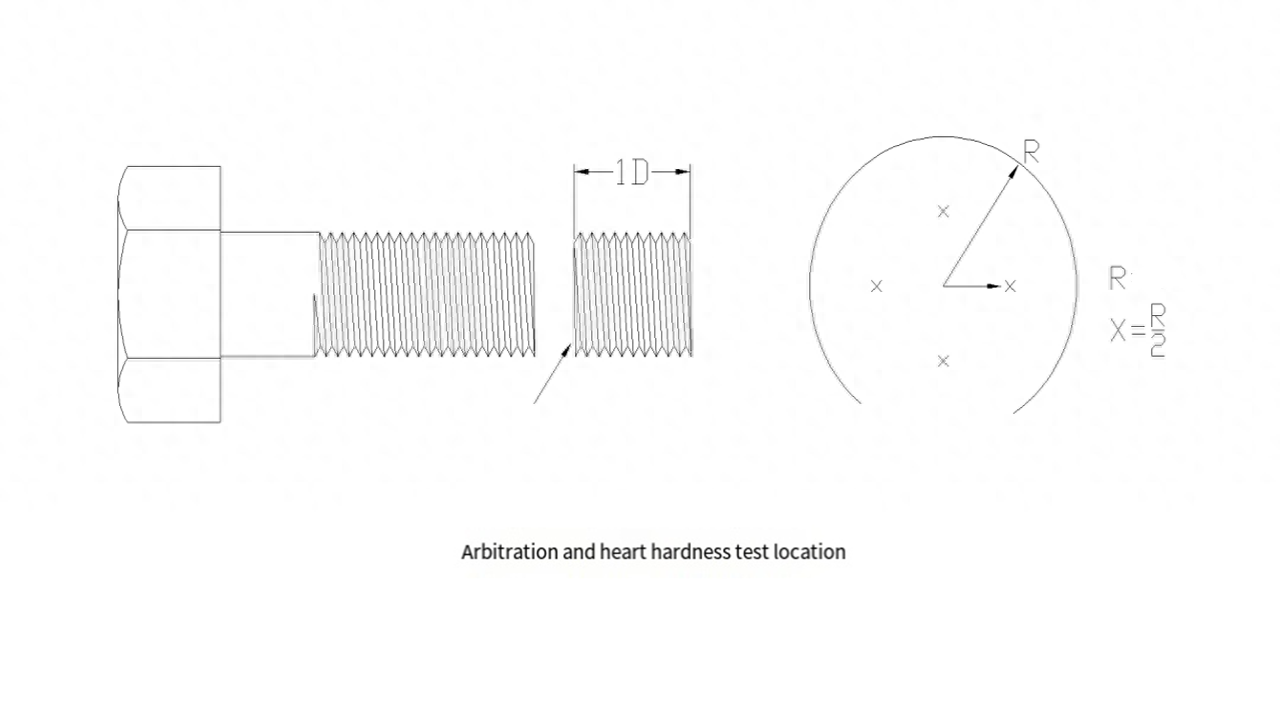

A cikin gano taurin kusoshi, babu maganin zafi na kusoshi, kawai buƙatar yin taurin saman, a cikin madaidaicin fushi akan layi.Idan kullin maganin zafi ne, ya wajaba a yanke taurin kan saman diamita a ƙarshen.Ana nuna matsayin gwaji a cikin adadi.Gwajin taurin yana a 1/2R akan saman, kuma taurin ya dace da ma'auni.

Bolt taurin yana da surface da kuma core, da surface yana nufin yin amfani da Vickers ko surface Rockwell taurin bayan cire surface tsatsa, da dai sauransu The core ya kamata a cikin kau da kai 1/2 diamita tsawo part a cikin surface da core. 1/2 wuri don wasa taurin, bambanci tsakanin taurin biyu ba zai iya wuce 30HV ba, saman yana da girma fiye da 30HV yana nuna cewa ba a yarda da carburizing na farfajiyar ba, Idan ƙasa ta kasance ƙasa da 30HV, yana nufin cewa an lalata ƙasa. , kuma ba a yarda ba.

Gabaɗaya goro 8 za a yi maganin zafi, amma ba a kula da zafi ba, goro 8 na yau da kullun ana yin shi da ƙarfe 35, gwajin taurin kuma an ƙayyade, saman gabaɗaya ba a buƙata, masana'antar maganin zafi. yana gwada taurin bayan maganin zafi, metric goro gabaɗaya ana karyewa daga tsakiya don gwada taurin zuciyarsa, gabaɗaya goro yana karye akan fuska ɗaya (wato a yanka wuƙaƙe biyu a saman), gwada taurin. na tsakiyar sashe na daya surface, da kuma kananan kwayoyi suna kullum sawa kashe sashe 0.2 ~ Gwada taurin bayan 0.3mm.4.6 ~ 6.8 kusoshi ba sa bukatar zafi magani;An baje shi don nau'in goro mai girma 2.

Ma'aunin GB3098.1 na ƙasa da ma'aunin GB3098.3 na ƙasa sun ƙayyade cewa ana auna taurin sulhu a radius 1/2 na ɓangaren giciye na ɓangaren.Idan akwai wani rikici yayin karɓa, za a yi amfani da taurin Vickers azaman gwajin sasantawa. Ya kamata a ɗauki akalla karatun 3 don kowane samfurin.

Wurin gwajin sasantawa: Lokacin bayar da rahoton sakamakon gwaji tsakanin mai siye da mai siyarwa don dalilai na sasantawa, gwajin taurin za a auna shi a tsakiya (r/2) na radius na saman da aka yanke diamita daya daga ƙarshen kusoshi ko ingarma.Idan girman samfurin ya ba da izini, ɗauki karatu 4 a ƙarshen wannan kusoshi ko tudu.Hakanan za'a iya gwada samfuran ƙananan diamita ta hanyar yin amfani da daidaitaccen yanki na tasha mai ɗaukar hoto daidai da saman da aka yanke.Don gwaje-gwaje na yau da kullun, ana iya gwada taurin kusoshi, skru ko studs a kai, wutsiya ko shank bayan an cire saman da ya dace.

Ga dukkan matakai, idan ƙimar gwajin ta wuce iyakar babba na taurin, ya kamata a cire samfurin daga matsayi na diamita maras tushe daga ƙarshen samfurin, da kuma tsakiyar samfurin da hanyar zaren a tsakiyar tsakiyar. gwajin, ƙimar sake gwadawa bai kamata ya wuce babban iyaka na tauri ba, idan cikin shakka, yakamata a karɓi taurin Vickers (HV) azaman yanke shawara.Gwajin taurin saman yana iya kasancewa a ƙarshen samfurin ko gefen hexagon, kuma wurin gwajin yakamata a ɗan yi ƙasa kaɗan ko goge don tabbatar da maimaitawar gwajin da ainihin yanayin saman samfurin.Ana amfani da HV0.3 a cikin gwajin sasantawa na gwajin taurin saman.Taurin saman da aka gwada tare da HV0.3 za a kwatanta shi da ainihin ƙimar gwajin ƙarfin ƙarfin da aka gwada tare da HVo.3, kuma bambancin ba zai wuce ƙimar taurin HV 30 ba.Taurin saman sama sama da ainihin taurin 30 HV ƙimar taurin suna nuna cewa samfurin an yi carburized.Don samfuran da maki 8.8 zuwa 12.9, ana iya amfani da bambanci tsakanin taurin saman da taurin asali don sanin ko samfurin yana da carburizing a saman.Taurin samfurin baya da alaƙa kai tsaye da ƙarfin juzu'i na ka'idar.Ƙayyadaddun ƙimar ƙima mafi girma ba bisa la'akari da iyakar ƙarfin babba ba.

Lura: Ya kamata a lura cewa bambance-bambancen haɓakar ƙimar ƙarfin ƙarfi yana haifar da aikin zafi mai zafi ko aikin sanyi.

Lokacin aikawa: Satumba-23-2023